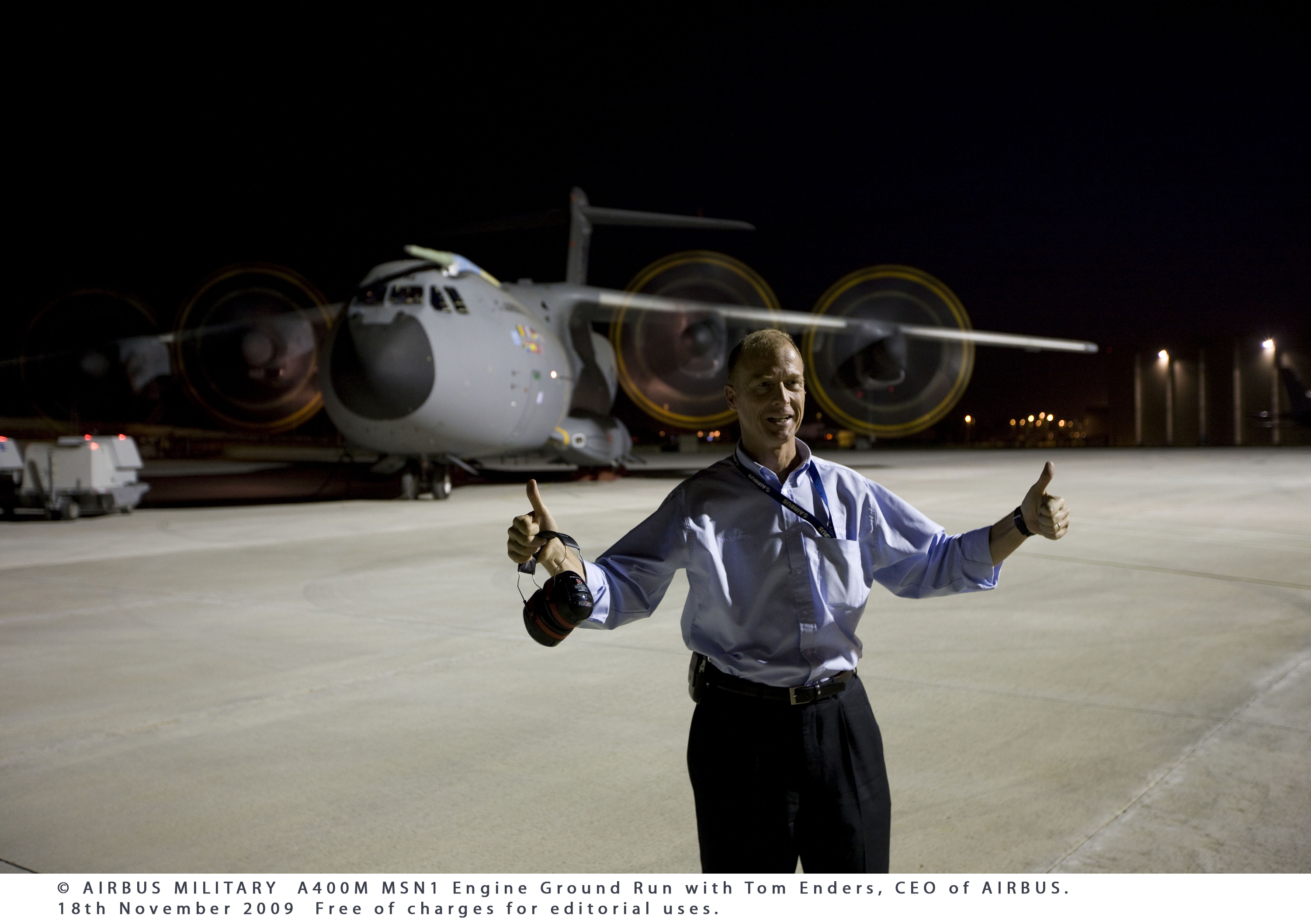

Tom Enders visits A400M facility in Sevilla

November 22, 2009

Airbus CEO met with flight test crew and engineers.

Tom Enders, CEO of Airbus, visited yesterday the A400M Final Assembly Line at San Pablo in

Seville and met with engineers conducting the ground tests of the new A400M military airlifter,

as well as with some of the flight crew preparing the aircraft for its first flight.

During a visit that lasted the whole afternoon he briefed on the progress of the programme,

which is expected to have its first flight before the end of this year. During the meeting with the

employees, he expressed his full support and thanked all those involved for their continued

effort and consistent contribution to the success of the project.

Mr Enders went on board the first A400M aircraft while it was being prepared for further tests

and inspected the cockpit and test equipment. He said he was extremely impressed with the

work that was being done.

“We have a great team working extremely hard, thanks to which we have made tremendous

progress over the past months. The excitement grows every day as we get closer to the first

flight of this fantastic aircraft,” said Tom Enders during the visit of the facility.

Later, the CEO was witness of an initial engine test.

First engine runs performed on A400M

November 22, 2009

Airbus Military achieved a key milestone in the A400M military airlifter programme when all four

Europrop International (EPI) TP400 turboprops on the aircraft were run simultaneously for the

first time on 18 November.

The event was the culmination of a series of tests in the previous 72 hours in which the engines

and propellers were first turned using ground power with no fuel in the fuel-lines, in a process

known as dry-cranking. Then they were turned with fuel in the lines but without starting the

engines, known as wet-cranking.

All four of the engines on aircraft msn 01 were successfully run for four hours beginning in the

early evening during an operation that lasted for 6.5 hours including preparation.

The engines ran at low power settings in ground-idle and flight-idle modes and will be run up to

maximum take-off power in further runs planned to take place shortly.

The operation at Airbus Military’s Seville, Spain facility was part of the procedure known as

destorage of the engines following the handover to the flight-test team at the end of the

previous week.

After the first full run, during which the engines performed flawlessly, the engine cowls were

opened and inspections showed that there had been no hot-air or fluid leaks.

On the subsequent runs the test team will continue exploring the behaviour of the engine itself

and also that of the aircraft systems that are powered by the engine.

Additionally the auxiliary power unit (APU), a separate small engine mounted on the aircraft

itself and designed to provide electrical power to the aircraft systems, was tested. It was used

to start the engines for the main engine run.

Airbus CEO Tom Enders, who personally witnessed the first full engine run-up, said: “I wish to

thank and congratulate the teams who worked extremely hard to reach this very important

milestone which paves the way to the A400M First Flight in the weeks to come.”

Fernando Alonso, Head of Flight Operations, added: “This is the first time we completely

powered up the aircraft using the engine power and the first time that the aircraft has been

operated completely autonomously.”

Cessna’s Pelton Calls for Public-Private Partnerships on Environmental Issues; Points to Aviation as a Model for Market-Driven Reductions

November 22, 2009

ENGHIEN-LES-BAINS, France, Nov. 20, 2009 The natural growth of the world’s general aviation industry may be stifled if industry and government fail to collaborate on environmental innovation, or arrive at parochial solutions that ignore the global interoperability of the world’s transportation systems, according to Cessna Aircraft Company Chairman, President and CEO Jack J. Pelton. Cessna is a Textron Inc. (NYSE: TXT) company.

Pelton made his remarks at Les Respirations annual international environmental congress held this year in Enghien-les-Bains just outside Paris. The event brings together speakers, scientists, doctors and government leaders to discuss air and water quality issues with topics including climate change, renewable energy, emissions trading and more.

“Aviation has established an outstanding track record in reducing its environmental impact as we grow to meet rising demand for transportation around the world,” Pelton said. “We must pursue policies and practices that balance progress and technology with environmental sensitivity.”

Globally, all of aviation accounts for only 2 percent of all CO2 emissions caused by burning fossil fuels, yet some seek to put an undue burden on it through unreasonable environmental regulation, Pelton said.

Pelton said over the past four decades, aviation has improved aircraft fuel efficiency by more than 70 percent at the same time passenger and cargo traffic was increasing more than six fold, making aviation an extremely greenhouse gas-efficient economic driver. During the same period, Pelton said jet engine fuel efficiency improved by 70 percent without government carbon emission standards, while federal emission standards for the auto industry enacted during the same period produced only about 15 percent improvement.

“It’s important to note these improvements are a result of customer demand and market forces, not regulation,” Pelton said.

Further reducing aviation’s impact on climate change requires partnership between industry and government and a commitment to find realistic solutions everyone can live with, Pelton said.

“If not, we risk damaging the growth and vitality of the aviation industry, one of the most dynamic, forward-looking and innovative sectors in the world, and an essential part of both the world’s transportation system and the global economy,” Pelton said.

Pelton pointed to Cessna’s recent eco-partnership with Greensburg, Kan., a city almost totally destroyed by a tornado in 2007 and now rebuilding itself as the world’s first “green” city.

Cessna, based nearby in Wichita, Kan., is supporting the effort with its expertise in areas such as engineering, program management and operations.

“Our hope is that this public-private collaboration serves as a model for other communities and businesses that wish to pursue environmental excellence,” Pelton said.

Cessna’s collaboration with Greensburg grew out of an idea generated by the Cessna Environmental Council, formed by Pelton in 2008 to develop and implement the company’s long-term environmental strategy.

Indian Civil Aviation Issues Type Certificate for Dassault’s Falcon 7X

November 22, 2009

(Teterboro, New Jersey, November 20, 2009) – Dassault Falcon has received

Type Certification for the Falcon 7X from the Director General of Civil Aviation

(DGCA) in India. This event confirms that the Falcon 7X meets all the rigorous

safety standards outlined by the country’s national airworthiness authorities and

allows registration of the Falcon 7X in India.

The first Falcon 7X in India will be delivered in January 2010 to Religare Voyages

Limited, a charter company based in New Delhi. This organization is also part of

a multi-billion dollar group with a global focus in financial services, diagnostics,

health & wellness, and IT services. Religare Voyages currently operates a Falcon

2000 as well as several smaller jets and turboprops. Their Falcon 7X will join

over a dozen Falcon 2000 and 900 models currently operating in India with

certificates.

A dozen additional large cabin aircraft are currently on order for customers in

India. The performance of the Falcons are especially valued here where short

airfields, elevated runways, and high temperatures are common. To bolster

support for the growing fleet, Dassault has established a spares center and

customer service team in Mumbai, as well as a liaison office in Delhi. Two

service centers approved by Indian DGCA are located in Mumbai.

“India has become one of our strongest markets over the past several years, so

the Falcon 7X type certification is of particular significance,” said John

Rosanvallon, President and CEO of Dassault Falcon. “As the country’s economy

continues to strengthen, there will be an increasing need to connect India

efficiently with other major centers of trade around the world. For example, the

Falcon 7X provides direct, non-stop access from Chennai, India to London City

Airport located in the center of London.”

The Falcon 7X is the first and only business jet to incorporate a digital flight

control system which provides greater operational safety and a smoother flight.

The aircraft also comes standard with the award-winning EASy flight deck,

designed to reduce pilot workload and improve pilot interaction through

enhanced situational awareness in the cockpit.

Announced at the Paris Air Show in 2001, the Falcon 7X was the first large cabin

jet to be simultaneously certified by the European Aviation Safety Agency

(EASA) and Federal Aviation Administration (FAA) on April 27, 2007. It is

powered by three highly reliable and efficient Pratt & Whitney Canada PW307A

engines which help to give the Falcon 7X greater airport performance and

increased peace of mind during long flights over water. The Falcon 7X also has a

15-30 per cent fuel efficiency advantage over other aircraft in the large cabin,

long range class. With a range of 5,950 nm (eight passengers, M.80 with NBAA

IFR reserves), the aircraft can comfortably connect 95 per cent of the commonly

used business aviation city pairs worldwide.

NAVAERO ANNOUNCES EFB CONTRACT WITH GOL FOR GLOBAL COMMUNICATIONS SYSTEM PROGRAM

November 22, 2009

CHICAGO IL USA November 20, 2009 — navAero announced today that GOL Linhas Aéreas Inteligentes S.A. the largest low cost airline and low fare airline in Latin America, has awarded a contract to navAero for the deployment of the t Bag™C22 EFB system for GOL’s fleet of B737NGs.

The EFB contract is a part of GOL’s implementation of an advanced program for a fleet-wide technology system of ACARS-through-Iridium reporting and management of their messages. The deployment of this system will bring the airline increased reliability and operations safety, greater control over performance of the aircraft and reducing and controlling costs through the reduction of aircraft weight and greater agility in the daily management of the airline. Additionally, the navAero EFB hardware will allow the airline to use the EFBs for data storage of currently used paper manuals that are carried on all flights. Less weight coupled with the utilization of sophisticated software applications hosted on the EFBs will allow Gol to have better tools to ensure maximum operational efficiency and better control costs.

“This type of communications platform anticipates future trends for airspace management”, states Captain Fernando Rockert de Magalhaes, Technical Vice President of GOL. “It will become increasingly common for communications between cockpit, flight coordination in airlines and air traffic controllers to be made by a number of text messages, and our implementation of this EFB and ACARS-through-Iridium will bring communications and technical advantages to the safety and cost management for our operations.”

Version:1.0 StartHTML:0000000199 EndHTML:0000016209 StartFragment:0000014714 EndFragment:0000016173 SourceURL:file:///Users/tomasch/Library/Mail%20Downloads/09-11-18%20navAero_GOL%237F2E88.doc

navAero will be implementing the deployment of its EFB hardware in collaboration with technology solutions for the ACARS-though-Iridium being provided by Avionica. The integrated technology/communications solutions will begin deployment in early 2010.

“This engagement with GOL represents an important milestone for navAero as we continue to expand our offerings to customers that interlink our EFB with technology systems from our strategic teaming partner, Avionica, to provide our airlines with integrated solutions that meet their business objectives.” said Ken Crowhurst, Executive Vice President, navAero, Inc.

“This bundled architecture of advanced EFB hardware and communications solutions will help increase the ability of commercial of airlines to realize maximum efficiency on the flight deck. We are looking forward to the implementation of this program and sharing this innovative technology with our current and future customers.”

Remarks by Boeing Commercial Airplanes President and CEO Jim Albaugh at groundbreaking for second 787 manufacturing line in North Charleston, S.C.

November 22, 2009

NORTH CHARLESTON, S.C., Nov. 20 /PRNewswire-FirstCall/ — “The Boeing Company (NYSE: BA) is an incredible company with a great heritage-including McDonnell Aircraft, Douglas Aircraft, Hughes Aircraft, North American Aircraft, and of course, Boeing-iconic companies all.

It’s a company that changed the 20th century. In World War II, we produced airplanes vital to winning the war. We helped put a man on the moon-we built the Saturn V rocket. We built the satellites that bring you the news live. And with the 707, we brought the world into the jet age.

I want you to know the kind of company you’re joining. This is a company that does the hard things. And I want to let you know that you are now part of the history of The Boeing Company.

The 787 Dreamliner will be the first new airplane of the 21st century. Some say that distinction belongs to the Airbus A380, but in my mind, that’s the last airplane of the 20th century.

The 787 will revolutionize how people travel. It will be more efficient, travel longer routes, be more passenger friendly and more environmentally friendly. And South Carolina will be part of this.

I came to visit here six weeks ago because I wanted to get an impression of the work force here. My impression was that the people here are hard working, dedicated, willing to learn and anxious to be a part of aerospace history.

Some would call this a win for South Carolina-and a loss for Washington state.

But there are no winners or losers in this. Our decision to come to South Carolina will be good for our competitiveness, for our customers, and for our country. And it will create jobs in both South Carolina and Puget Sound.

Before I go further, let me say a word to the community leaders and elected officials here. You sold us on South Carolina. You helped make this possible. Gov. [Mark] Sanford, Sen. [Lindsey] Graham, Sen. [Jim] DeMint and everyone who worked so hard–thank you.

Let me take a moment to introduce your newest resident-Marco Cavazzoni, the new vice president and general manager, Final Assembly and Delivery, Charleston. He will lead the new site.

And I’d also like to reintroduce you to Tim Coyle, our vice president who oversees the current site.

Let me close by saying that today is an important day for all of us. But it is only a first step. This is the first step in delivering hundreds of jets to our customers. But more importantly, it is the first step in developing a world-class aerospace capability in South Carolina.

To our future employees-welcome to Boeing. You, along with 160,000 other Boeing employees, will continue to change the world.

I know that the senator needs no introduction, but let me tell you how I know him. He is a tireless supporter of our troops; he ensures they get the best equipment and support. He makes sure American servicemen and servicewomen have the advantage because they have the tools they need. He is a tireless supporter of U.S. industry, its manufacturing and free trade. He is a great friend of Boeing.

Senator Lindsey Graham.”

Boeing Breaks Ground on Second 787 Assembly Line in North Charleston, SC

November 22, 2009

Boeing facility expands production capability and increases footprint in South Carolina

NORTH CHARLESTON, S.C., Nov. 20 /PRNewswire-FirstCall/ — Boeing (NYSE: BA) today held a groundbreaking ceremony to mark the start of construction for the second final assembly site for the 787 Dreamliner program at its Boeing Charleston facility. The facility also will have the capability to support the testing and delivery of airplanes.

“Today’s event marks the beginning of an expansion plan that will strengthen the 787 program and allow us to continue building on the footprint we have established in South Carolina with Boeing Charleston and Global Aeronautica,” said Jim Albaugh, president and CEO of Boeing Commercial Airplanes. “Locating the second line in North Charleston will allow Boeing to successfully compete in the aerospace market and grow for the long-term benefit of many stakeholders.”

Today’s groundbreaking ceremony was attended by Albaugh; South Carolina Gov. Mark Sanford; Sen. Lindsey Graham; Sen. Jim DeMint; Rep. Henry Brown; Rep. James Clyburn; State Sen. Hugh Leatherman; State Sen. Glenn McConnell; State Rep., Speaker of the House Bobby Harrell; Charleston County Council Chairman Teddie Pryor, Sr.; North Charleston Mayor Keith Summey and other key officials from South Carolina. Anita Zucker, chairperson and CEO of The InterTech Group, Inc., served as master of ceremonies for the event.

Boeing Charleston performs fabrication, assembly and systems installation for the 787 aft fuselage sections. Global Aeronautica, which is 50 percent owned by Boeing, is responsible for joining and integrating 787 fuselage sections from other structural partners.

“We look forward to expanding our capability in South Carolina through our existing site, while maintaining our commitment to the Puget Sound region where Boeing Commercial Airplanes remains headquartered,” said Albaugh. “Puget Sound will continue to design and produce airplanes, including the 787.”

The 787 Dreamliner will be more efficient, quieter and have lower emissions than other airplanes while offering passengers greater comfort and the convenience of direct, nonstop flights between more cities around the world. Fifty-five customers around the world have ordered 840 787s since the program was launched in April 2004, making the Dreamliner the fastest-selling new commercial jetliner in history. The 787 family of airplanes will carry 210 to 330 passengers on flights up to 8,500 nautical miles (15,750 km).

First Boeing 747-8 Freighter Leaves Paint Hangar

November 22, 2009

EVERETT, Wash., Nov. 18 /PRNewswire-FirstCall/ — Boeing (NYSE: BA) moved the first 747-8 Freighter out of the paint hangar in Everett, Wash., Tuesday night sporting a special “light” livery.

Painted white with blue accents, the 747-8 Freighter unveiled a new twist on the Boeing Commercial Airplanes livery. It features an oversized “8” on the background of the tail as well as “747-8” on the belly.

The light livery, which saves time and expense compared to the full Boeing livery, will remain on the airplane until the flight-test program is completed. After flight test, it will be refurbished and delivered to a customer.

The first freighter will begin preparing for the necessary tests leading up to first flight in early 2010.

Octubre/Noviembre

November 19, 2009

All the Coolest From NBAA 09

November 18, 2009