ITT Enhances Chip-on-Flex Filter Connectors with TVS Surge Suppression Capabilities

June 15, 2009

PARIS, FRANCE – June 15, 2009 – ITT Interconnect Solutions, a leading global manufacturer and supplier of connectors, interconnects, and cable assemblies, has enhanced its Chip-on-Flex (CoF) filter connectors with TVS Surge (TVSS) suppression capabilities. The new CoF filter design features one standard flex per layout and utilizes a flexible circuit internal to the connector, with chip capacitors surface-mounted on a small pad adjacent to the feed-thru contact.

“The flex circuit design provides the necessary platform to surface mount TVS devices for lightning strike protection,” said Keith Teichmann, director of marketing for ITT Interconnect Solutions. “This allows us to mount off-the-shelf devices for both filtering and surge protection using automated manufacturing processes, resulting in a highly cost-effective, compact, and lightweight design while still providing the robust, high performance filter connector required of many applications, including those in the military arena.”

Tested to MIL-DTL-38999 Series III mechanical shock, vibration and high altitude DWV specifications, the CoF filter connectors exceed 1000 cycles of thermal shock per MIL-STD-1344. The CoF connectors feature contact count counts from one to 600 and are available in rack and panel, circular and D-subminiature configurations. The compact, lightweight connectors provide up to 15% space savings compared to standard MIL-DTL-38999 configurations.

Customizable circuit values are also available by adding or removing the chip capacitor and TVS devices. ITT also offers complete design and design change capabilities.

Typical pricing for the Chip-on-Flex filter connectors is approximately $175 each. Lead time is from 12 to 14 weeks ARO.

Atlantic Airways Orders CFM56-5B-powered Airbus A319

June 15, 2009

LE BOURGET, France — June 15, 2008 — Atlantic Airways, the national airline of the Faroe Islands, has selected the CFM56-5B engine to power the Airbus A319 the airline ordered in 2008. Atlantic Airways placed a firm order with CFM on the first day of the 2009 Le Bourget Air Show. The airline is scheduled to take delivery in 2011.

Atlantic Airways, which was established in 1987, plans to operate its new aircraft on regular flights between Faroe Islands and Denmark, as well as other European countries. The engines will be the advanced CFM56-5B Tech Insertion configuration.

“We chose the CFM56-5B as we believe this product provides us the best overall solution when you take into account reliability, performance economics and environment,” said Mr. Magni Arge, president and CEO of Atlantic Airways.

“We are very pleased to welcome Atlantic Airways as a new CFM customers especially in current economic environment,” said Claude Poulain, vice president of sales for CFM International. “Our commitment is to provide the high quality product and world-class support that Atlantic Airways is counting on.”

Tech Insertion engines will bring significant operational benefits for Atlantic Airways. Over the engine’s life cycle, CFM56 Tech Insertion will provide the airline better specific fuel consumption, which translates to better fuel burn and, as a result, lower CO2 emissions. The engine also meets the new International Civil Aviation Organisation (ICAO) Committee of Aviation Environmental Protection standards (CAEP /6) that took effect in early 2008.

Tech Insertion will also result in longer time on wing through an equivalent 15 – 20° C additional exhaust gas temperature margin; between 5 and 15 percent lower maintenance costs (depending on the thrust rating) through enhanced durability. These benefits are achieved through improvements to the high-pressure compressor, the combustor, and the high- and low-pressure turbines.

CFM56-5B engines are a product of CFM International, a 50/50 joint company between Snecma (SAFRAN Group) and General Electric Company.

From left to right, Claude Poulain, vice president sales, CFM International; center, Magni Arge, president and CEO, Atlantic Airways; right, Jean Massot, executive vice president, sales and marketing, CFM International.

GE and NASA To Begin Wind-Tunnel Testing This Summer of Open Rotor Jet Engine Systems

June 11, 2009

EVENDALE, Ohio – June 11, 2009 – Following several months refurbishing

a special NASA test rig, GE Aviation and NASA this summer will begin a

wind-tunnel test program to evaluate counterrotating fan-blade systems

for “open rotor” jet engine designs.

The testing will be conducted throughout 2009 and early 2010 at wind

tunnel facilities at NASA’s Glenn Research Center in Cleveland, Ohio.

This is not a full engine test, but a component rig test to evaluate

subscale fan systems using GE’s and NASA’s advanced computational

tools and data acquisition systems.

In the 1980s, GE successfully ground-tested and flew an open-rotor jet

engine that demonstrated fuel savings of more than 30 percent compared

with similar-sized, jet engines with conventional, ducted front fan

systems. Since then, GE has dramatically advanced its computational

aero-acoustic analysis tools to better understand and improve

open-rotor systems.

“The tests mark a new journey for GE and NASA in the world of open

rotor technology,” said David Joyce, president of GE Aviation. “These

tests will help to tell us how confident we are in meeting the

technical challenges of an open-rotor architecture. It’s a journey

driven by a need to sharply reduce fuel consumption in future

aircraft.”

GE and the Fundamental Aeronautics Program of NASA’s Aeronautics

Research Mission Directorate in Washington are jointly funding the

program. Snecma (SAFRAN Group) of France, GE’s longtime 50/50 partner

in CFM International, a highly successful joint company, will

participate with fan blade designs.

For the NASA tests, GE will run two rows of counterrotating fan

blades, with 12 blades in the front row and 10 blades in the back row.

The composite fan blades are 1/5 subscale in size. They will be

tested in simulated flight conditions in Glenn’s low-speed wind tunnel

to simulate low-altitude aircraft speeds for acoustic evaluation, and

also in Glenn’s high-speed wind tunnel to simulate high-altitude

cruise conditions in order to evaluate blade efficiency and

performance.

Engine noise is a prime challenge in operating open-rotor engines in a

commercial aviation environment.

NASA’s test rig, now refurbished and modernized, was actually used in

the 1980s when NASA and GE first tested scale-model, counterrotating

fan systems that led to the development of the open rotor GE36 engine.

***

The first wind-tunnel tests this summer will essentially reenact those

1980s tests. GE and NASA will first run blades of the same design

that led to the original GE36 jet engine. This will establish

critically important baseline data for GE for flight test correlation

because the GE36 in the 1980s flew on Boeing 727 and MD-80 aircraft.

As new and more exotic fan blade designs are run in the wind tunnel,

GE and NASA will be able to assess comprehensive aero and acoustic

design space in order to better understand how these designs will

perform in an actual operating environment.

In total, GE and NASA will run six different sets of blades in the

NASA wind tunnels, including five sets of modern blade designs. GE

designed and fabricated the scale-model blades at its Cincinnati

facility using technical input provided by the GE Corporate Research

Center in New York.

Open-rotor jet engine designs are among the longer-term technologies

being evaluated for LEAP-X, CFM International’s (GE/Snecma) technology

program focusing on future advances for next-generation CFM56 engines.

Embraer Holds 40th Anniversary Commemorative Activities

June 10, 2009

Initiatives focus on all who have participated in the Company’s history

São José dos Campos, June 10, 2009 – As a part of the program remembering the 40 years

since its founding, on August 19, 1969, Embraer has been following through on a series of

activities for employees and their families, as well as for the communities where it is

involved, and the general public, in honor of the people who have already contributed, or now

contribute, to building this success story. At the same time, they demonstrate the Company’s

concern for establishing responsible corporate social practices, with sustainable growth and

the development of the communities where it is located.

On June 5, Embraer celebrated World Environment Day by planting 40 trees at each of its six

facilities in Brazil. Three are in the city of São José dos Campos, and the others in the cities of

Botucatu, Gavião Peixoto, and Taubaté, in outstate São Paulo, where the planting was done

by 40 employees at each unit who have been with the Company the longest. A similar

initiative was done by students and staff from Engineer Juarez Wanderley High School,

created and maintained by the Embraer Education and Research Institute.

Recently, a contest was held among employees in Brazil and abroad for painting a model

of the EMBRAER 190 airplane, under the theme of “Embraer’s 40 Years”. In July,

another contest for the children of Company employees, will have the topic of “The

Aircraft of the Future”.

Also in July, for the purpose of publicizing the history of aviation, as well as that of Embraer,

itself, the Company will take a traveling exhibit to some of Brazil’s airports and cities. At the

same time, the Company will inaugurate the Embraer Historical Center portal, where Internet

users can navigate through Embraer’s history.

In October, with the support of the Embraer Education and Research Institute and the City of

São José dos Campos, the Embraer Miniglider Championship will be held, focusing on public

school students, through middle school in the cities where Embraer has industrial plants.

In the context of the celebrations, Embraer will present some of its aircraft that are no

longer in production, duly restored, like it did, in 2008, with the second prototype of

the Bandeirante airplane, the first produced by the Company. The plan is to promote

the history of the Brazilian aeronautics industry and make it known to the general

public, through exhibits in aerospace museums around Brazil.

Two prototypes of the CBA 123 aircraft, designed in the early 1990s, were very carefully

restored by Embraer, in a partnership with the National Industrial Apprenticeship Service

(Serviço Nacional de Aprendizagem Industrial – SENAI) unit in São José dos Campos. The

first airplane is ready and was presented in May, and the second is in the final recuperation

phase, which should be concluded in August.

Embraer’s origin dates back to the 1940s, when the Brazilian government began structuring the

bases of the modern aeronautics industry in Brazil. First, the Aeronautics Technical Center

(Centro Técnico de Aeronáutica) – now called the Aerospace Technology General Command

(Comando-Geral de Tecnologia Aeroespacial – CTA), was organized, in 1946, followed by the

founding of the Aeronautics Technological Institute (Instituto Tecnológico de Aeronáutica –

ITA), in 1950, both of which are located in the city of São José dos Campos, in outstate São

Paulo, Brazil.

In 1968, the twin-engine Bandeirante turboprop flew, originally carrying nine passengers

and developed by CTA in line with the requirements of the IPD-6504 Program of the

Aeronautics Ministry. Under the leadership of then-CTA Director, Colonel Paulo Victor da

Silva, and Major Ozires Silva, the first Director-Superintendent of Embraer, the project

gathered momentum, resulting in the founding of the Company, a year later.

Don Campion Inductee for FATA Hall of Fame

June 8, 2009

Don Campion, President of Banyan Air Service, is the 2009 Inductee for the Florida Aviation Trades Association (FATA) Entrepreneurial Excellence Hall of Fame.

This award was established in 2006 to honor those who have made significant contributions to the business aviation industry in Florida. These visionaries have acted not only on their dreams but also drawn on their professionalism and integrity to ensure the aviation industry will flourish and inspire others to make aviation their career and commitment.

“FATA was honored to receive the nomination of Don Campion as this year’s recipient of the Entrepreneurial Excellence Hall of Fame award. His nomination was unanimously approved by the Board of Directors. Don joins others who have persevered to not only fulfill a dream but also continue to improve and add to their visions for aviation in Florida,” stated Paula Raeburn, FATA Executive Director.

On May 20th, a bronze plaque of Don Campion was hung in the Hall of Fame at Embry-Riddle Aeronautical University in Daytona Beach, FL. On the evening of June 16, 2009, Campion will once again be honored during a dinner at the FATA Annual Conference where he will be presented a crystal award.

Don’s entrepreneurial spirit allows him to continually visualize and improve services for the aviation community. A few of his many achievements include:

• Banyan has been consistently voted a top United States fixed base operation (FBO) and is currently recognized as the #3 best Independent United States FBO. Professional Pilot PRASE Survey 2009.

• the recent opening of Jet Runway Café, a breakfast and lunch café with an aviation theme

• the opening of the new Banyan terminal in 2006

• key contributor to obtaining extended hours at U.S. Customs at Fort Lauderdale Executive Airport 2005

• serving on the NATA Board from 1999-2002

• serving as President of the FXE Airport Association

• serving on the Everglades University Aviation’s Program Advisory Committee

• participating as a member of both the “FBO 20 Group” and “Vistage”

• fostering a learning environment for schools groups with facility tours

• providing an excellent work environment for teammates which includes a gym, company Chaplain, health benefits, and assisting with expenses for teammate’s flying lessons

Continued from page 1

• Philanthropic Work that includes helping others through aviation:

o Challenge Air

o Angel Flight

o Mission Work in Nigeria

o Various community projects

Located at Fort Lauderdale Executive Airport, Banyan is a 24-hour full-service FBO now celebrating 30 years of operation with an array of comprehensive aviation services; aircraft fuel and ground services, turbine airframe and engine maintenance, avionics installations and repairs, aircraft sales, Hangar63 (Banyan’s Aviation Store) and Jet Runway Café.

Banyan employs 140 aviation professionals who cater to aircraft owners and operators from Central and South America, the Caribbean, Bahamas, and the United States.

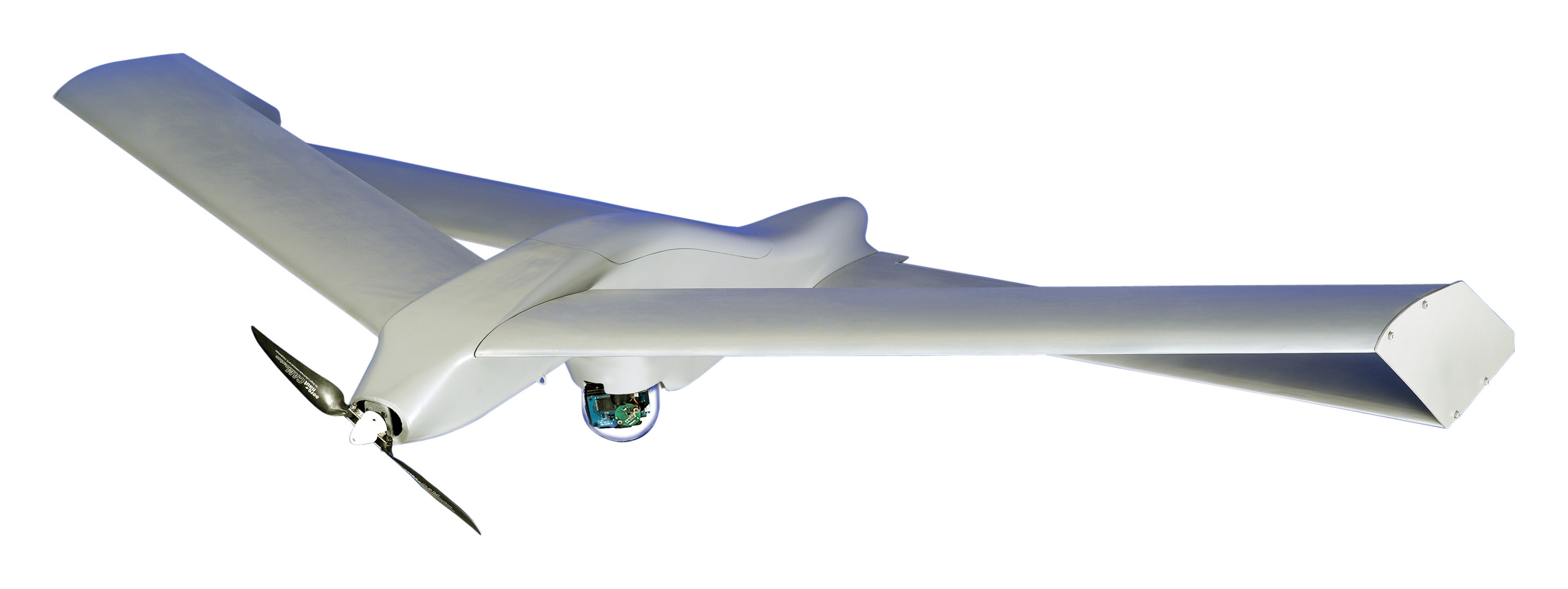

BENTAL’S MICROBAT DEBUTS IN PARIS AS AN INTEGRATED SYSTEM ON INNOCON’S MICRO FALCON UAV PLATFORMS

June 2, 2009

MicroBat will be Marketed as, and Become Part of, All Innocon Micro Falcon UAV Platforms

Israel, June 02, 2009 – Bental Industries, Ltd., Israel’s defense industry leading electric motion and power systems supplier and its source for micro and mini UAV stabilized payload systems, will integrate its proven MicroBat-275 on Innocon’s Micro Falcon UAVs. Bental’s Starter Generator systems have already been integrated on Innocon’s Mini Falcon UAV platforms. Intended to be announced at this year’s Paris Air Show, this new agreement takes the companies’ cooperation to another level by ensuring that now, MicroBat will be an integral part of Innocon’s Micro Falcon. Innocon will therefore, market its Micro Falcon UAVs with Bental’s MicroBat integrated from the start, as part of each platform.

“This is an important step in our efforts to team up with other companies for the purpose of integrating our systems on their platforms”, said Bental’s CEO Shmuel Mandel. He further pointed out that, “Innocon’s MicroBat selection as the second Bental system integrated onboard their mini and micro UAVs, underscores, yet again, the experience based confidence that our partners and clients have in our systems. Making our MicroBat integral to, and marketed as part of Innocon’s Micro Falcon UAV platforms, mark another step in the way our systems are understood and used by designers and producers of cutting edge platforms of all types”.

Intended for integration on a variety of air, land, and sea platforms, MicroBAT is an operational system integrated on different types of air and land UAVs as well as on a variety of other platforms. Claimed the world’s smallest and most compact stabilized payload system for mini and micro UAVs, MicroBAT meets the complex and evolving challenges of surveillance, reconnaissance, and observation missions. The MicroBAT family includes models for various platform sizes, and it is ideal for use in a wide range of small UAV applications including VTOL. Designed for both day and night operation, this rugged, light, and powerful stabilized system seamlessly integrates its camera to enable precise control of zoom, shutter, and focus from the air or by ground operators. With its remarkable flexibility, the MicroBat-275 can be mounted almost anywhere on practically any type of platform.

Airbus Military A330 MRTT dry contact with a new refuelling pod

June 1, 2009

The Airbus Military A330 MRTT has successfully performed first contacts using a new generation of under-wing hose and drogue refuelling pods

The Airbus Military A330 MRTT (Multi Role Tanker Transport) has completed another major milestone performing successfully a series of dry contacts using the new generation Cobham 905E hose and drogue refuelling pods, located under the wings. The receiver aircraft was a Spanish Air Force F/A-18A+ fighter.

The system performed well in hose extension and retraction, and showed good hose response in the contact as well as stability during pre-contact and when connected.

This new refuelling pod is a development of the 907E pod already in service with the Canadian and German air forces on their A310 MRTTs. The pods can each deliver up to 420 US gal/min (1600 litres/min) through a 90 ft (27.4 m) hose, and are controlled from a state-of-the-art Fuel Operator Console located in the cockpit.

“The next steps in the flight test program involve more contacts with the new hose and drogue refuelling pod and the advanced Aerial Refuelling Boom System (ARBS), refuelling a variety of receivers that will include French, Portuguese and Spanish small and large receiver aircraft. This flight test phase will lead us to the completion of military certification, and final qualification with our customer” said Miguel Morell, Vice President Airbus Military Derivative Programmes.

The A330 MRTT has been selected by the air forces of Australia, the United

Kingdom, Saudi Arabia and the United Arab Emirates, and was chosen last year by the U.S. Air Force for its recapitalization of the service’s aging tanker fleet.

Embraer Delivers 100th Super Tucano Aircraft

May 26, 2009

Caption: Frederico Fleury Curado (right), Embraer President & CEO, and Air Force General Juniti Saito, Aeronautics Commander, during the delivery ceremony of the 100th Super Tucano, on May 26.

Brazilian Air Force receives this advanced training and light attack airplane

São José dos Campos, May 26, 2009 –

Embraer delivered the 100th Super Tucano aircraft, today, at the Company’s

headquarters in São José dos Campos, State of São Paulo, Brazil. The Brazilian Air Force

(Força Aérea Brasileira – FAB) established the technical-operational requisites for this

advanced turboprop, designated as the A-29 by the FAB, which has ordered 99 aircraft,

and now receives this commemorative unit.

“We are proud to deliver the 100th aircraft specifically to the FAB, which was the first to operate

the Super Tucano,” said Orlando José Ferreira Neto, Embraer Executive Vice President, Defense

Market. “The FAB’s ability to establish challenging requisites that reflect real operating

conditions was of paramount importance to our development of such a successful airplane. As a

result, the Super Tucano offers the market’s best solution for more efficient tactical training, and

the best operational adaptation, by incorporating leading edge technologies.”

Out of a total of 169 units sold, so far, Embraer has orders from the Air Forces of Chile, the

Dominican Republic, and Ecuador. The Super Tucano currently operates successfully with the

Brazilian and Colombian Air Forces on air space surveillance and operational missions.

The Super Tucano, in its single- and two-seat versions, entered service with the FAB in

December 2003, to be used both to train pilots and to fly operational missions. This flexibility

makes the Super Tucano the only aircraft in production, in the world, that is capable of handling

advanced pilot training, surveillance, and counter-insurgency missions, including at night, with

the aid of night-vision goggles, and electro-optical and infra-red sensors. It also operates on

rustic airfields and with a wide variety of qualified external load configurations.

Bombardier Aerospace Employee Receives Prestigious Aviation Award

May 20, 2009

(CASI) awarded Larry Dufraimont, Director of Flight Test and Flight Operations at Bombardier’s

Flight Test Centre in Wichita, Kansas, the prestigious Trans-Canada Trophy, the oldest aviation

award in Canada. Mr. Dufraimont received this award for his outstanding achievements in the

field of air operations.

At Bombardier Aerospace, Mr. Dufraimont leads a multi-discipline team in the modification and

instrumentation of test aircraft and in the planning and execution of flight testing for all

Bombardier Aerospace business jets and regional aircraft. He worked at the company from

1993 (then de Havilland) to 1997, returning in 2000.

Mr. Dufraimont began his career with the Canadian Air Force, where he had the opportunity to

fly 36 aircraft types as a T-33 and CF-5 Instructor Pilot, VIP Transport Pilot and Qualified Test

Pilot. Highlights from his 23-year career in the military were his graduation from the UK Empire

Test Pilot School and the ten years he spent as a Qualified Test Pilot with the Canadian Military

Aerospace Engineering Test Establishment (AETE) flying numerous fighter and transport

aircraft including the de Havilland Augmentor Wing Powered Lift Research aircraft which he flew

for NASA. He retired from the Air Force as a Lt. Colonel having served in several leadership

positions over his career.

Mr. Dufraimont moved on to civil aviation, where he has spent 19 years in the Canadian and

U.S. aerospace industry. He has held many leadership positions in Flight Test, Ground Test,

Program Management and Engineering for Bombardier Aerospace, Rockwell Collins and

Boeing.

The TransCanada

Trophy, also known as the McKee Trophy, was established in 1927 by

Captain J. Dalzell McKee. In 1926, Mr. McKee, of Pittsburgh, Penn., accompanied by Squadron

Leader Earl Godfrey of the RCAF, flew from Montreal to Vancouver in a Douglas MO2B

seaplane. McKee was so impressed by the services provided by the RCAF and the Ontario

Provincial Air Service, that he set up an endowment by means of which the greatly coveted

McKee Trophy is awarded to the Canadian whose achievements were most outstanding in

promoting aviation in Canada

The Alenia Aermacchi M-346 “MASTER” makes its first three aircraft formation flight.

May 14, 2009

The 60-minute flight was made by the two prototypes and LRIP00, representative of the series production configuration, while the M-311 aircraft acted as camera ship.

Alenia Aermacchi is proceeding with the last M-346 development activities and is fitting out the new hangar dedicated to the automated build-up and structural assembly lines for series production at a rate of 18-24 aircraft annually, which can be increased in case of specific needs.

Thanks to the extremely advanced and automated industrialization process, Alenia Aermacchi will be able to address effectively the market demand for trainers aimed at pilots of 4th and 5th generation combat aircraft. Presently the M-346 “MASTER” has been chosen for a total of more than 60 aircraft and there are going to be other commercial opportunities through the participation to important international bids.